- Agitators, and 9+ as an independent consultant) in the design of agitation systems, specializing in fermentation and bioreactors. Currently his company does general engineering, mixing and bioreactor design consultation, including design of pilot programs, equipment specification and bid evaluation. Customers include Abengoa.

- Agitator Type: Top Entry Design Code: EEUA Options available: Motor Position: Vertical and Horizontal Shaft Seal: Single & Double Mechanical and Stuffing Box Vessel Type: With and Without Baffle Material: SS304, SS304L, SS316, SS316L, C22, CS and Custom to add Bottom Shaft Support: With and Without.

- Agitators for minerals and metal industry offered, are robust designs with proven track records for a wide range of applications such as Crystallization, Dissolution, Extraction, Flotation, Leaching, Oxidation, Precipitation, Storage etc.

- Agitator Design Calculation

- How To Design Agitator

- Agitator Mixer Design

- Agitator Design Software Online

Inputs for agitator design: Design pressure: 6 kg/cm 2 / F.V. Design temperature: 75°C to 200°C Vessel working capacity: 6.3 KL Vessel inside diameter (D): 1950 mm Vessel T.L.-T.L. Length: 2200 mm Maximum mixing speed (N): 150 RPM Density of working fluid: 1000 kg/m 3 Viscosity of working fluid: 10000 CP MOC: Hastelloy C-22. Agitadores Agitaser is a company that has been designing and manufacturing industrial agitators since 1942. Our expertise in the treatment of liquids.

Introduction to agitator design:

Agitators are machines used in industries for mixing fluids. In industries mixing of fluids is necessary for many chemical processes. It may include mixing of liquid with liquid, gas with a liquid, or solids with liquid. Mixing is accomplished by the rotating action of an impeller in the continuous fluid. Type of fluid and its physical state, the degree of agitation and geometry of vessel are key factors in the design and selection of agitator components.Here we will discuss the design of agitator vessel based on practical data inputs as given below:Inputs for agitator design:

Design pressure: 6 kg/cm2 / F.V.Design temperature: 75°C to 200°CVessel working capacity: 6.3 KLVessel inside diameter (D): 1950 mmVessel T.L.-T.L. length: 2200 mmMaximum mixing speed (N): 150 RPMDensity of working fluid: 1000 kg/m3Viscosity of working fluid: 10000 CPMOC: Hastelloy C-22Solution:

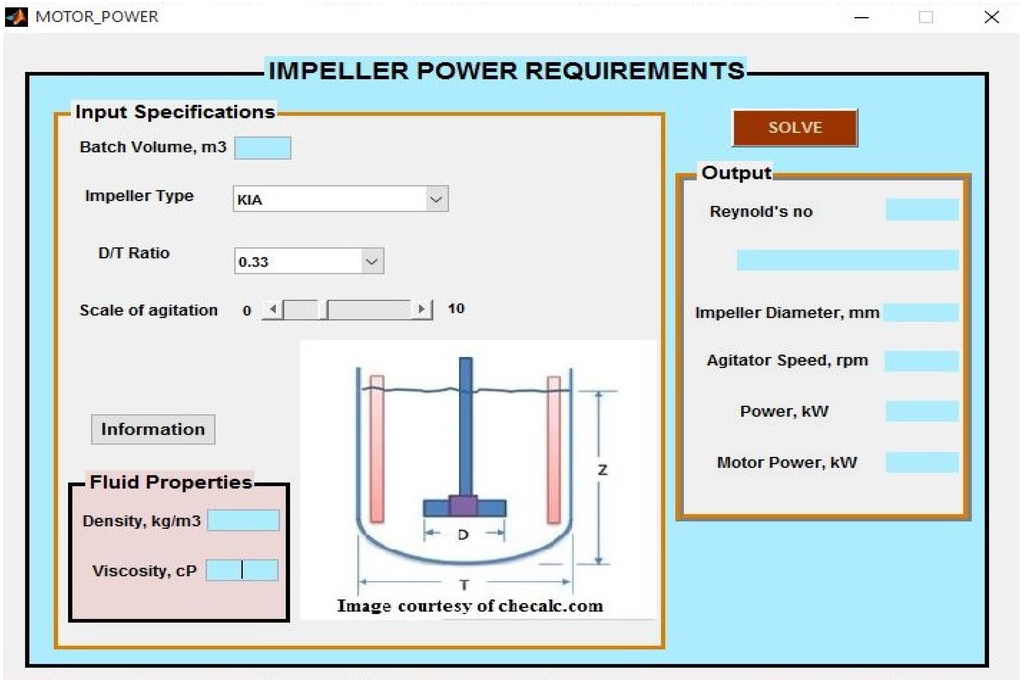

Step-1: Power calculations and selection of motor

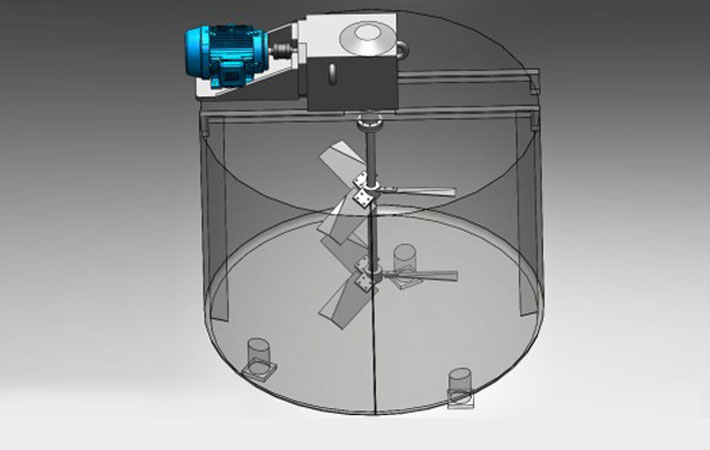

For required power calculations, selection of the type of impeller is very important to achieve required agitation power. Selection of impeller is done based on application and type of flow. Flat paddle, turbine, anchor type, pitched blade impellers are used most commonly. For given type of agitation flat paddle impeller is used as given below:After selection of impeller dimensionless number Reynold’s number is calculated as given belowRe = ρ*N*d5/ µFrom generic agitator curve, as shown in Fig.1, impeller power number is calculated based on calculated Reynold’s number.Fig. 1 – Power number against Reynolds number of some turbine impellers [Ref. Bates, Fondy, and Corpstein, Ind. Eng. Chem. Process. Des. Dev. 2(4) 311 (1963)]Based on impellers selected the layout of the shaft is done as shown in Fig.2.Fig.2 Agitator assembly layout

Agitator Design Calculation

Step 2: Design of shaft

Design of solid shaft subjected to shear stressFor selected motor power rated torque and maximum torque is calculated as given below:Rated torque: Tr = P*4500 / 2*π*NMaximum torque: Tm= (1.5 to 2.5) TrTherefore, solid shaft diameter is calculated byTm = π* ζ*ds3/16Step:3 Design of solid shaft subjected to pure bending

Maximum bending force is assumed to be acting at the point of jamming i.e. 0.75 of maximum agitator radius from the axis.Maximum bending force Fm = Tm/0.75*rMaximum bending moment Mm= π*бb*ds3/32Step:4 Design of solid shaft subjected to bending and twisting

According to maximum shear stress theory for ductile material, equivalent twisting moment is calculated asTe = √(Mm2+Tm2) = π* ζ*ds3 /16According to maximum normal stress theory for brittle material, equivalent bending moment is calculated asTe = ½ ( Mm+√(Mm2+Tm2) ) = π*бb*ds3/32Larger of all calculated diameters is considered as the minimum required diameter of the shaft. Therefore, selecting shaft diameter of 100mm, the shaft is checked for critical speed.

/16According to maximum normal stress theory for brittle material, equivalent bending moment is calculated asTe = ½ ( Mm+√(Mm2+Tm2) ) = π*бb*ds3/32Larger of all calculated diameters is considered as the minimum required diameter of the shaft. Therefore, selecting shaft diameter of 100mm, the shaft is checked for critical speed.Step:5 Design of solid shaft based on critical speed

Maximum deflection (∆) due to bending force and corresponding critical speed (Nc) is calculated as follows,∆ = WL3 / 3EINc = 946/√∆Agitator should be designed to operate at less than 70% of the critical speed. Since selected 100mm dia. shaft is failing at critical speed, select next standard shaft of diameter 120mm and perform the calculations for critical speed.

/ 3EINc = 946/√∆Agitator should be designed to operate at less than 70% of the critical speed. Since selected 100mm dia. shaft is failing at critical speed, select next standard shaft of diameter 120mm and perform the calculations for critical speed.Thus required solid shaft diameter is 130mm.

How to Select the Best Design of Mixer or Agitator for your Processing Needs. No Downloads. 40,193 On SlideShare. 0 From Embeds. 0 Number of Embeds. Agitator Design and Selection Standard Engineers vineet.shroff@gmail.com 2.

- We are looking at designing a pressure vessel that has a center mounted agitator on. Design of Agitators. And products defined by software.

- Free Do-more Designer Software Download. Live Chat; Agitator Power Consumption Calculation - Industrial. More about Agitator Simulation Software Download.

Lab Mount / Hand HeldGrovhac lab mount mixers & agitators mount to a vertical lab stand, and are sold with or without the stand. Hand held agitators are for use with 5-gallon pails and feature a self positioning clamp. | Stanchion MountStanchion mount agitators mount to a 1″ vertical pipe and allow vertical positioning on the pipe. |

C-Clamp MountGrovhac c-clamp mount mixers & agitators clamp to the walls of drums, tanks, or on to mixer stands. Adjustable c-clamp allows positioning of the mixer shaft for optimum results. | Bridge Mount w/ C-ClampsBridge mount mixers & agitators feature a horizontal, cross-the-tank bridge which supports the mixer's head. Bridge is secured to tank by heavy-duty c-clamps; mixer head and c-clamps are adjustable across the bridgework, allowing these mixers to adapt to tanks of all shapes and sizes. |

Tote Mount (Bridge Mount w/ Tote-Clamps)Grovhac tote mount mixers & agitators are specifically designed for use with totes. These mixers feature a horizontal, cross-the-tank bridge which supports the mixer's head. Bridge is secured to tank by heavy-duty tote-clamps; mixer head and tote-clamps are adjustable across the bridgework, allowing these mixers to adapt to totes of all shapes and sizes. | Saddle-Plate MountThe saddle plate of these mixers allows permanent mounting to mixer stands or tanks, while the ball & socket assembly provides adjustment of mixer shaft angle. |

Flange MountGrovhac flange mount mixers & agitators permanently mount to tank or mixer support. Flange mount mixers are available with a variety of flange sizes and materials, with or without a stuffing box or double mechanical seal. | Drive Unit for Drums w/ Built In AgitatorsThese drive units are for barrels or drums with built in agitators; drive unit mounts directly on the drum and mates up with agitator shaft. Shin koihime musou otome ryouran sangokushi engi download. |

2″ NPT Bung MountGrovhac bung mount mixers & agitators thread directly into a 2″ NPT bung. Collapsible mixing blades allow easy entry and removal from the bung. | Cover MountFor use with open top drums or pails, cover mount agitators are designed to mount on our stainless steel drum or pail covers. Download mask pro 4.1 full+crack. |

High Speed DispersersGrovhac now carries High Speed Dispersers! Our high speed dispersers are available in a wide range of drive types including single speed electric, variable belt electric, variable hydraulic and electric inverter. Grovhac dispersers are designed with varying degrees of shear as dictated by the product to be mixed. In addition, we now carry Dual Shaft Mixers, Coaxial Mixers, Ribbon Blenders, and Sigma Blade Mixers. Contact us to learn more about these new products!

| Mixer AccessoriesA wide variety of accessories, replacement parts, and mixing blades for our Agitator and Heavy Duty Mixer lines. |

CademPVD is the most intelligent CADEM software for the mechanical design of pressure vessels, storage tanks, heat exchangers, reactors, agitators, mixing vessels. It is an integrated software which covers various national & international design codes.

How To Design Agitator

- Pressure Vessels module covering complete design of Receivers and General Equipment.

- Pressurised Equipment with arrangement for Cooling / Heating.

- Pressurised Equipment with arrangement for Mixing / Agitation.

- Pressurised Equipment with arrangement for Mixing / Agitation along with jacketing for Cooling / Heating.

- Tall process columns like Distillation Still, Scrubbers etc.

- Shell and Tube type Heat Exchangers.

- Design of Agitator Shafts for Mixing Tanks and Reactors.

- Large API Storage Tanks covering Atmospheric and Pressurized Tanks.

- MS Self supported Chimney Stacks.

- Design of Pressure Vessels, Jacketed Vessels, Mixing Tanks and Reactors as per ASME Sec. VIII Div. 1, EN 13445, IS 2825 Codes.

- Design of Shell & Tube Heat Exchangers as per ASME Sec. VIII, Div 1 and TEMA Codes.

- Design of Columns as per ASME Sec. VIII Div. 1 and Wind & Seismic analysis as per H.H. Bednar and other references.

- Design of Agitator Shaft as per EEUA.

- Atmospheric Storage Tank design as per API 650.

- Low Pressure Storage Tank design as per API 620.

- Design & Sizing of Floating Roofs (Pontoon & DDFR) for API Storage Tanks.

- Chimney design as per IS 6533 Code.

- All components of Pressure Vessels, Heat Exchangers and Reaction Vessels under both internal & external pressure.

- Agitator Shafts directly supported by gear box bearings or with intermediate bearing housing; with or without bottom bush support.

- All components of Columns & Chimneys under wind, seismic, deflection conditions, including their base plate and anchor bolt sizing.

- Built-in material properties database.

- Database of wind and seismic codes & information.

- Unmatched quality of design documentation with all relevant code clauses, formulae, formulae substitutions and intermediate results.

32 Years of equipment design experience captured, polished, compacted and is now ready for transfer to designers, fabricators & plant engineers. read more >>

Downloads

How to Download?

How to Install?

CademPVD Guide

CademPVD Feedback

Engineering Services

Our SERVICES team has expertise and experience in mechanical design & engineering of various kinds of process plants equipment and piping systems.

Agitator Blade Design

Equipment Engineering

Agitator Design Calculation

How to install car mods in gta san andreas without sami. Piping Engineering

Process & Instrumentation Diagram

Structure Analysis & Design

Finite Element Analysis

Technical Software Development

Training & Implementation

Power Plant & High Pressure Steam Piping Engineering

News & Events

Agitator Mixer Design

Visit us at - MAHATech 2018 Exhibition

Date: 8th - 11th February, 2018

Agitator Design Software Online

Stall No - A-54

Venue: New Agricultural College Ground, Shivaji Nagar, Pune, Maharashtra.